Electronics, Firmware, and Real-World Constraints Most Founders Miss

So you’ve got an idea for a smart product.

Maybe it’s a:

- Health wearable

- Sensor device for industrial use

- Bluetooth-enabled controller

- Environmental monitor

- Or a connected tool with embedded logic

You can describe what it should do. You know who it’s for. Maybe you even have a 3D render or industrial design sketch.

But what most founders don’t realize is this:

Physical products don’t run on ideas. They run on tightly integrated electronics, firmware, and mechanical decisions — all constrained by real-world physics, components, and manufacturing limits.

At Veebar, this is exactly what we engineer — end-to-end product systems for founders building tech-enabled hardware.

Here’s what it actually takes.

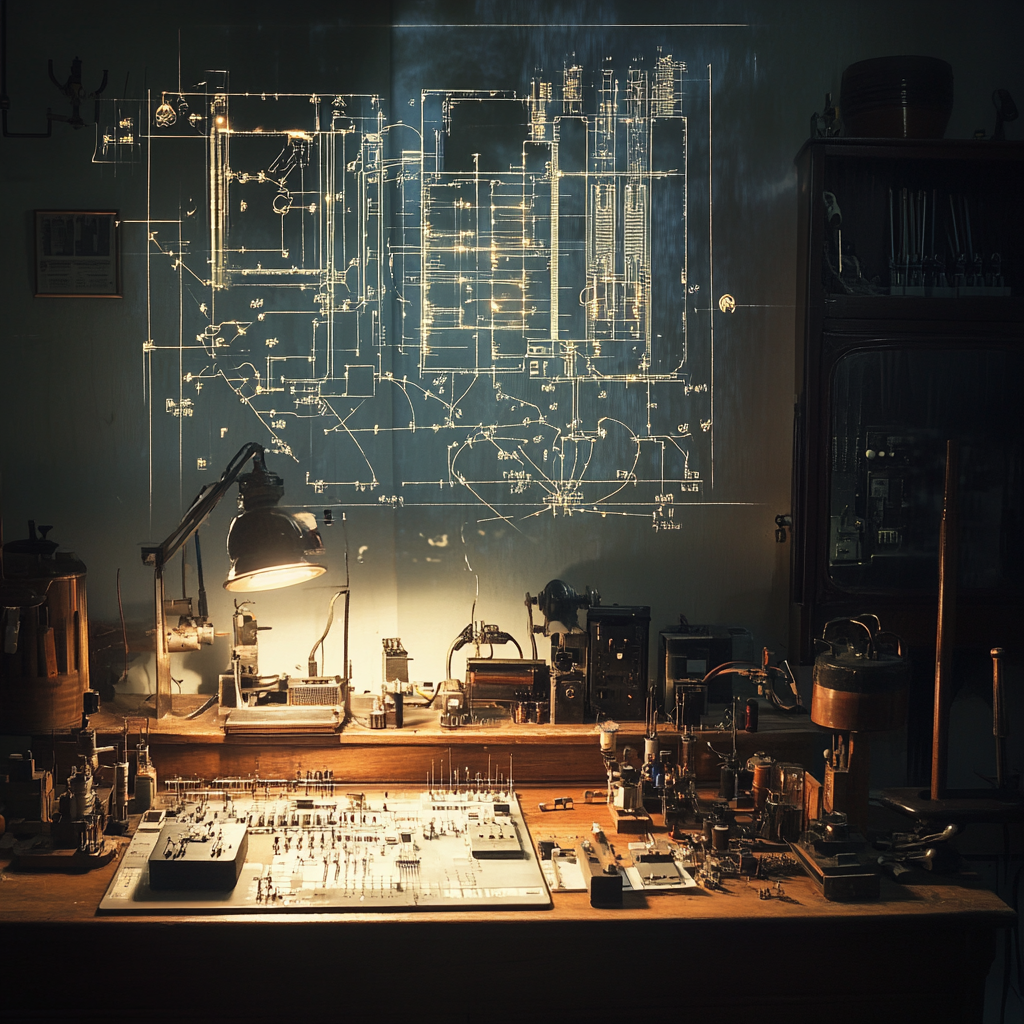

1. Electronic Architecture: Picking the Right Core Components

The first critical decision is how the product functions electrically.

We engineer this architecture based on real-world constraints like power, connectivity, and footprint.

Key components we design for:

- MCU (Microcontroller Unit): What processor runs the logic? STM32, ESP32, Nordic nRF, etc.

- Sensor Suite: What are you measuring? Temp, motion, proximity, EMG, etc.

- Communication Modules: Bluetooth Low Energy (BLE), Wi-Fi, LoRa, NFC, or proprietary RF

- Power Strategy: Battery-powered? USB-C? Rechargeable or swappable cells?

- PCB Design Constraints: Single-layer vs. multi-layer, rigid vs. flexible PCBs, EMI shielding

Everything here must balance cost, function, and available board space.

And we build with DFM (design for manufacturability) from day one — not just to prototype, but to scale.

2. Firmware Development: Making the Product Actually Work

Once the electronics are defined, we develop the firmware — the embedded code that runs the device.

What firmware actually controls:

- Sensor polling logic

- Sleep/wake cycles for battery conservation

- Bluetooth pairing protocols

- Data filtering (e.g. smoothing noisy signals)

- Communication with companion apps or servers

- On-device error handling and recovery

We typically write in C/C++, sometimes with RTOS (Real-Time Operating Systems) depending on complexity.

Bonus: If your device needs OTA (Over-the-Air Updates) later, we build the bootloader + memory partitions to support that from day one.

3. Mechanical Constraints: It All Has to Fit

Here’s where most designs fall apart:

You can’t just throw sensors into a case and call it a product.

We engineer around:

- Heat management for enclosed devices

- Antenna placement so BLE doesn’t drop

- Ingress protection (IP rating) if you need water/dust resistance

- Shock tolerance and mounting if used in industrial environments

- Accessibility for assembly/testing — if your product can’t be built or tested easily, you’ll pay for it later

All this feeds into how we build your enclosure, fasteners, seals, and final part tolerances.

We typically prototype with CNC, SLA, and multi-material 3D prints — moving into injection tooling only once your design is fully tested.

4. Power + Battery Design: Every mA Counts

Power strategy is one of the most overlooked parts of product development — but it determines real usability.

We calculate:

- Average + peak current draw for all functions

- Battery size and chemistry (LiPo, Li-ion, coin cells, etc.)

- Charging strategy — onboard? Swappable? Wireless?

- Sleep mode logic — devices that wake on interrupts, not timers, save huge power

- Safety logic — undervoltage, thermal cutoff, reverse polarity protection

This isn’t just about “making it work” — it’s about making it last, reliably, across hundreds or thousands of units.

5. System Integration: Hardware, Firmware, and Apps Working Together

If your product connects to a web app or mobile interface, we design that system flow too.

We map:

- How the firmware communicates with mobile/desktop apps

- What data is sent (raw vs. processed)

- How real-time or offline sync needs to work

- Secure pairing + authentication methods

- Which actions are handled on-device vs. in the cloud

You don’t want to build firmware that needs to change every time your front-end team updates a setting.

That’s why we design the product as a system — not as isolated parts.

What You Actually Get Working with Veebar

If you’re a non-technical founder trying to bring a product to life, here’s what we deliver:

- Electronics architecture and full PCB design

- Firmware development with OTA-ready support

- Mechanical CAD and functional prototyping

- Power and battery design optimized for cost and longevity

- System-level planning that includes cloud/app sync if needed

- A prototype that works. Not just looks good.

We build for DFM, scalability, and investor readiness — from day one.

📩 Contact us if you’re building a smart product and need an engineering partner who speaks business and builds hardware that works — not just decks and mockups.